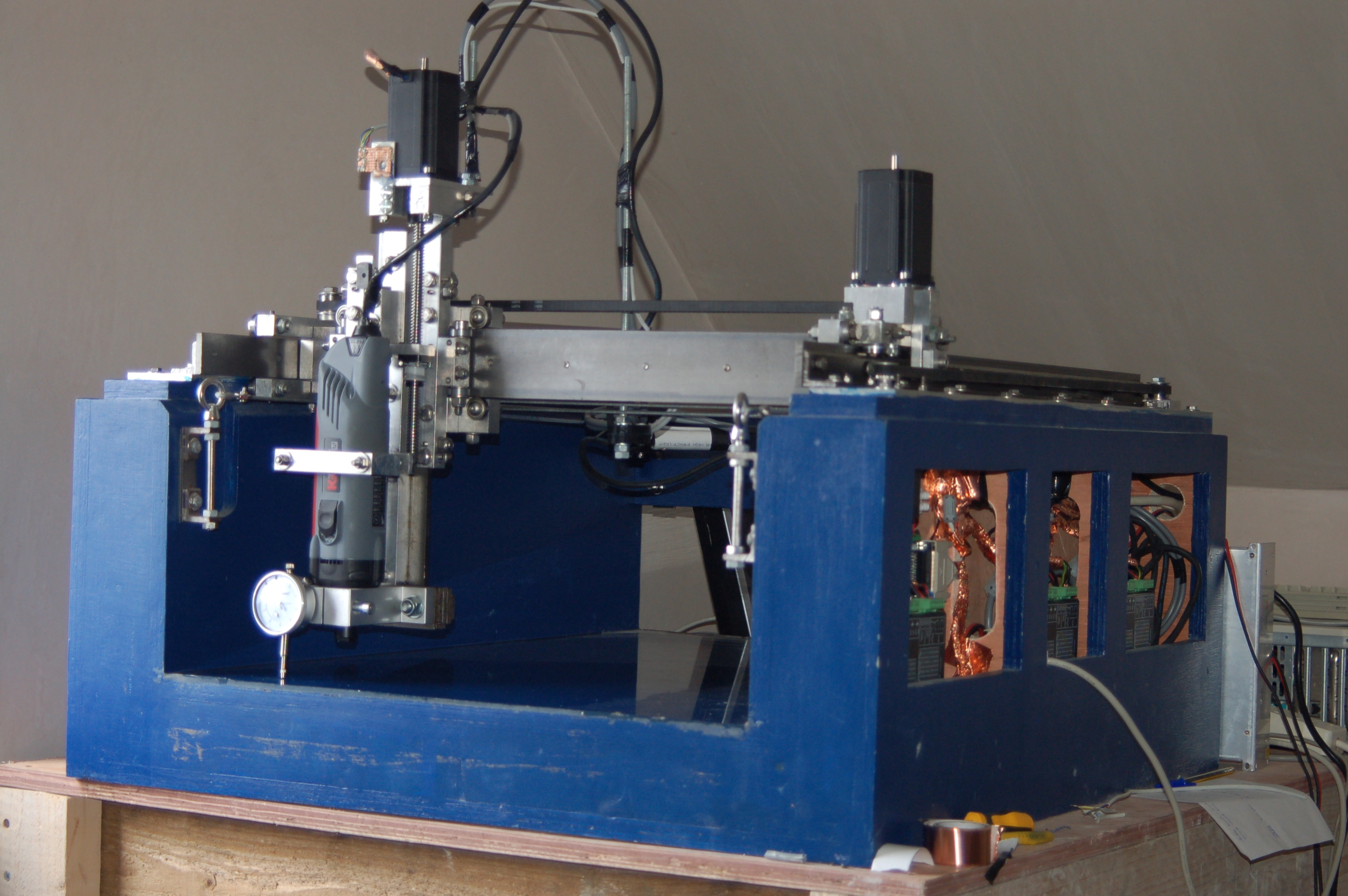

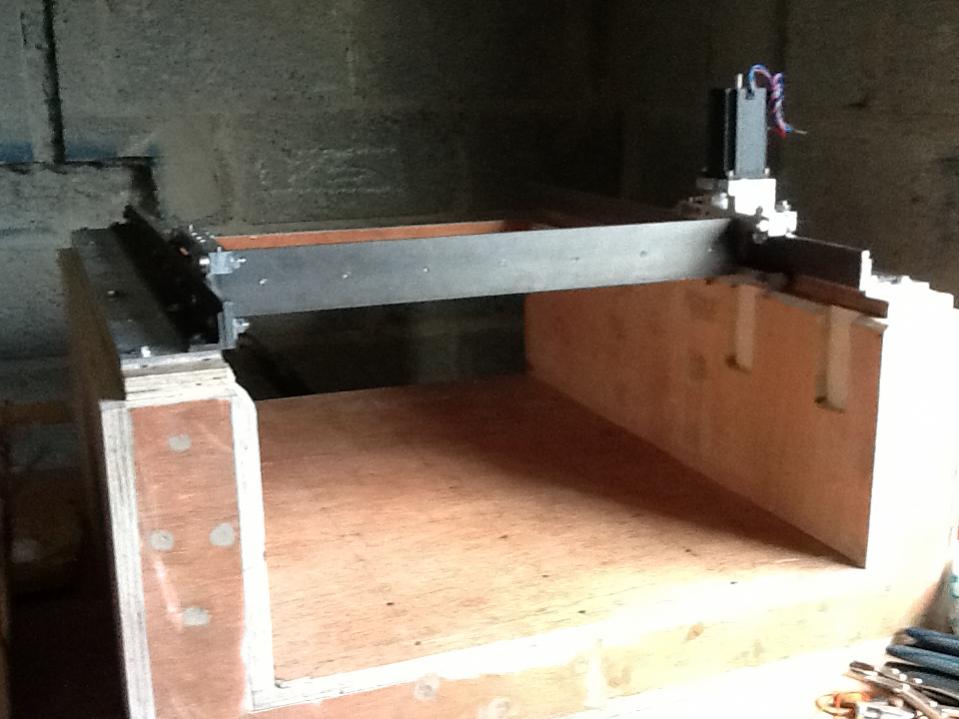

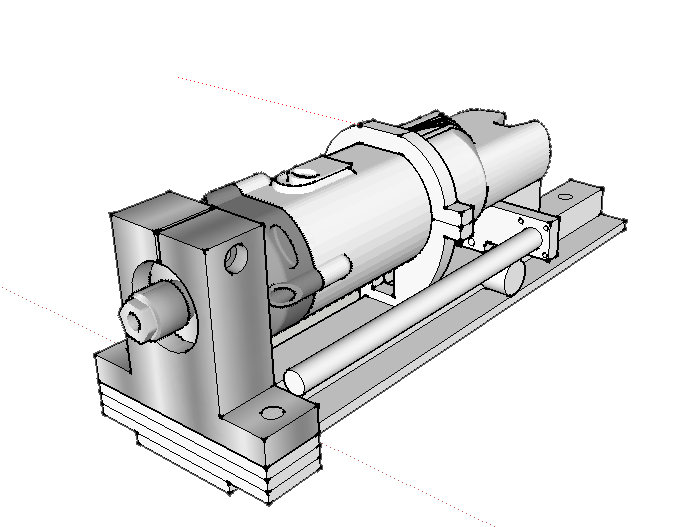

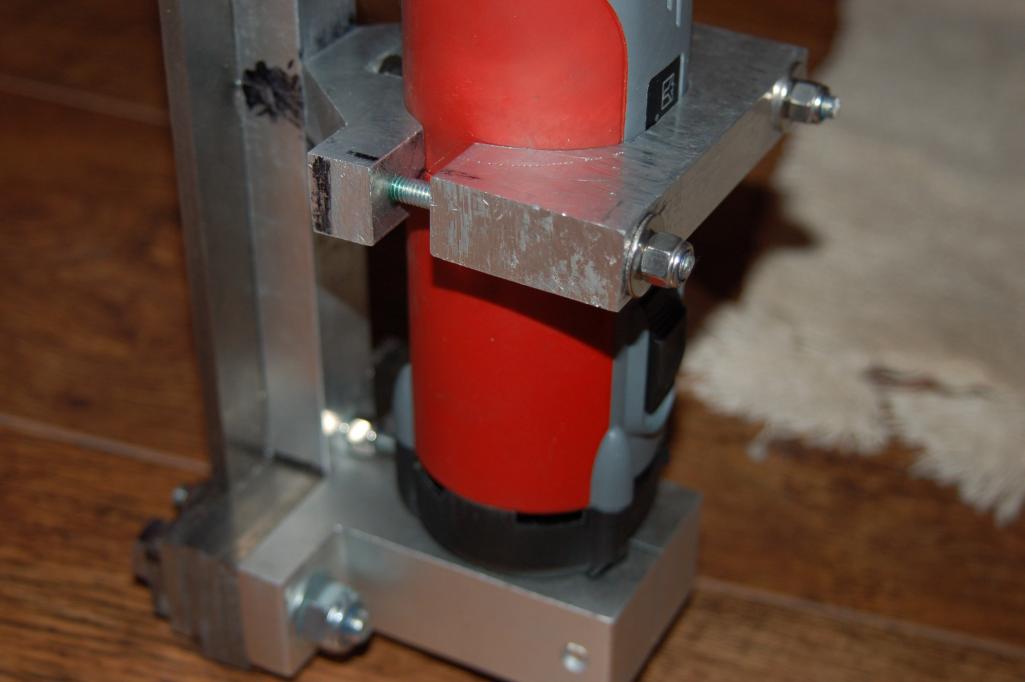

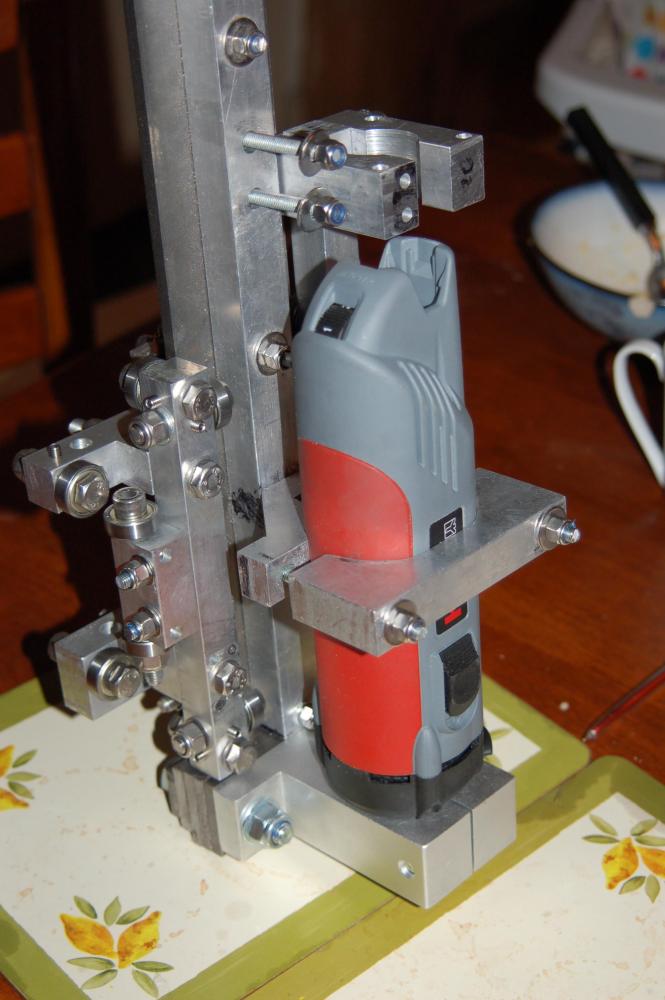

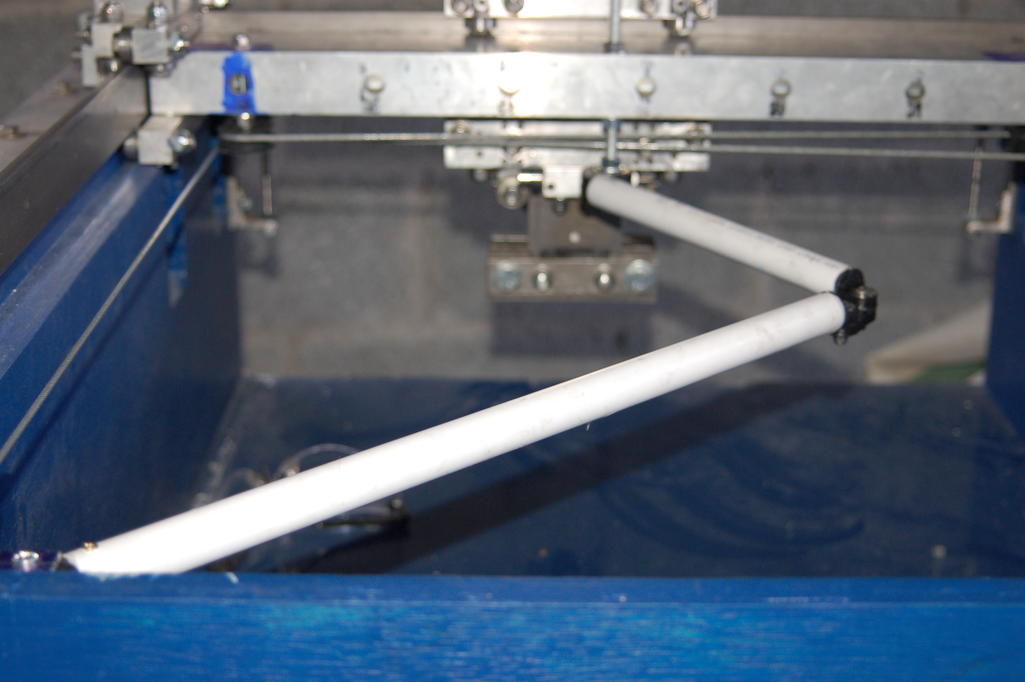

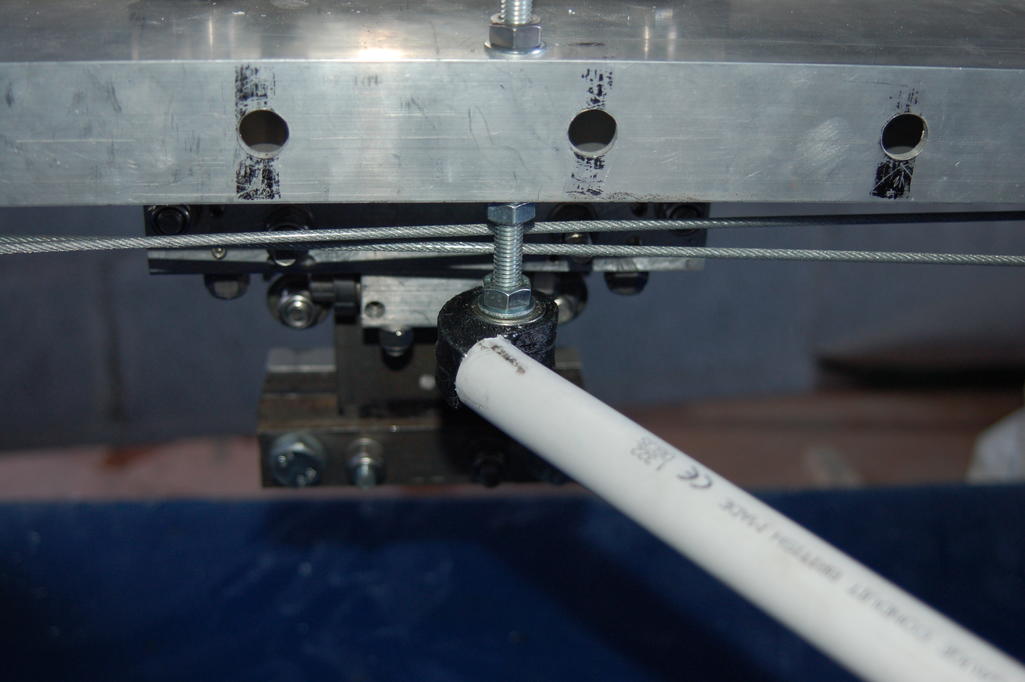

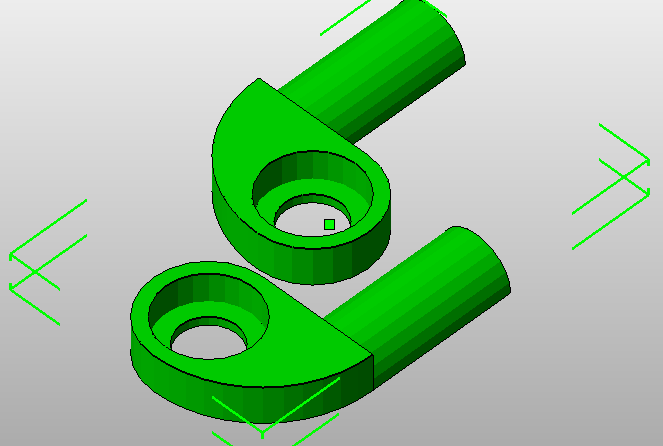

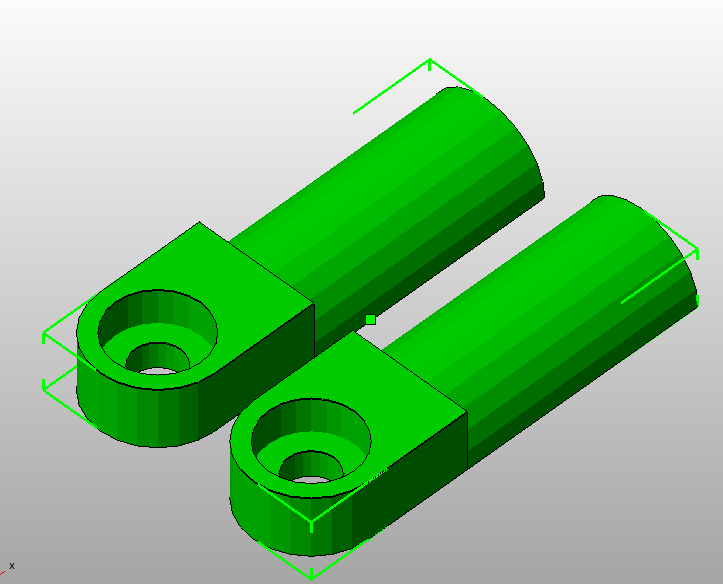

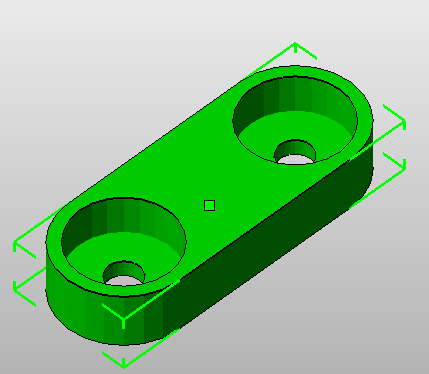

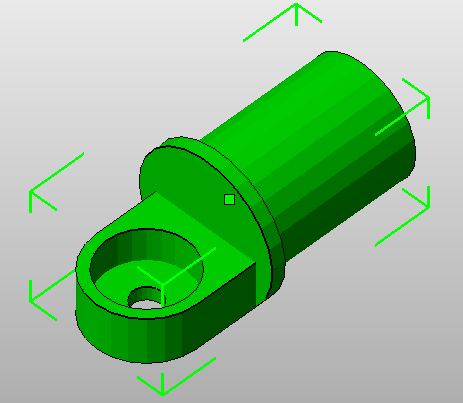

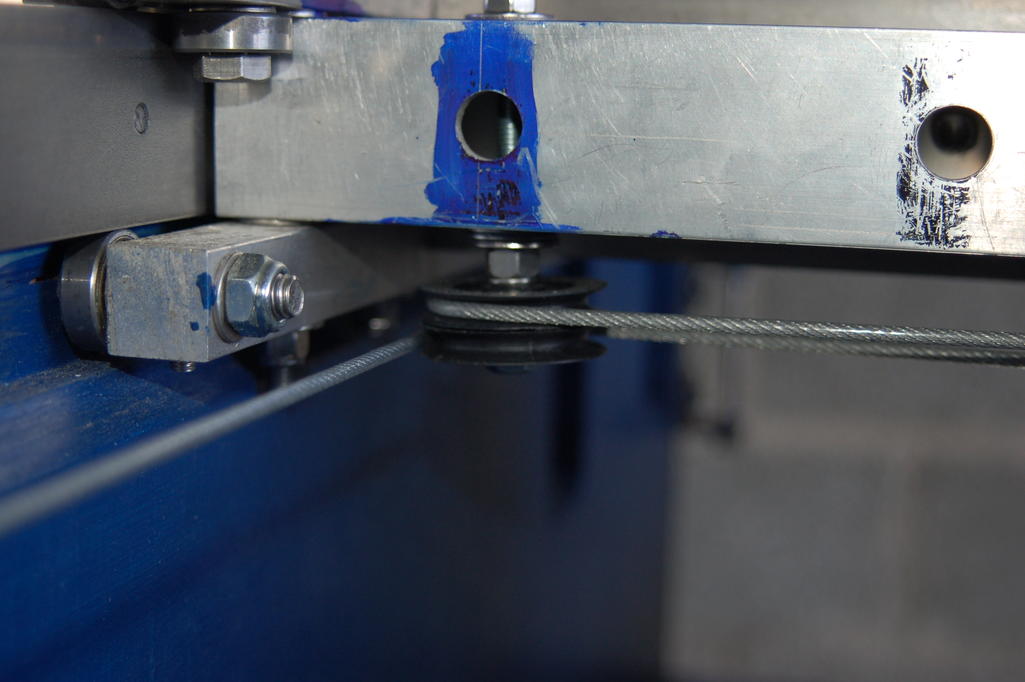

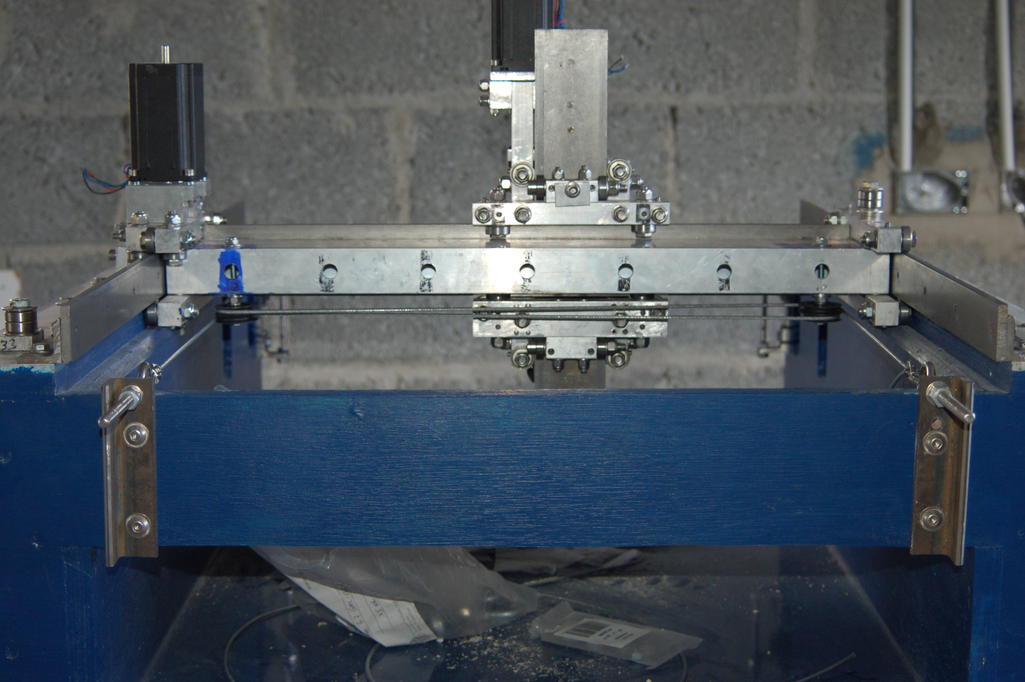

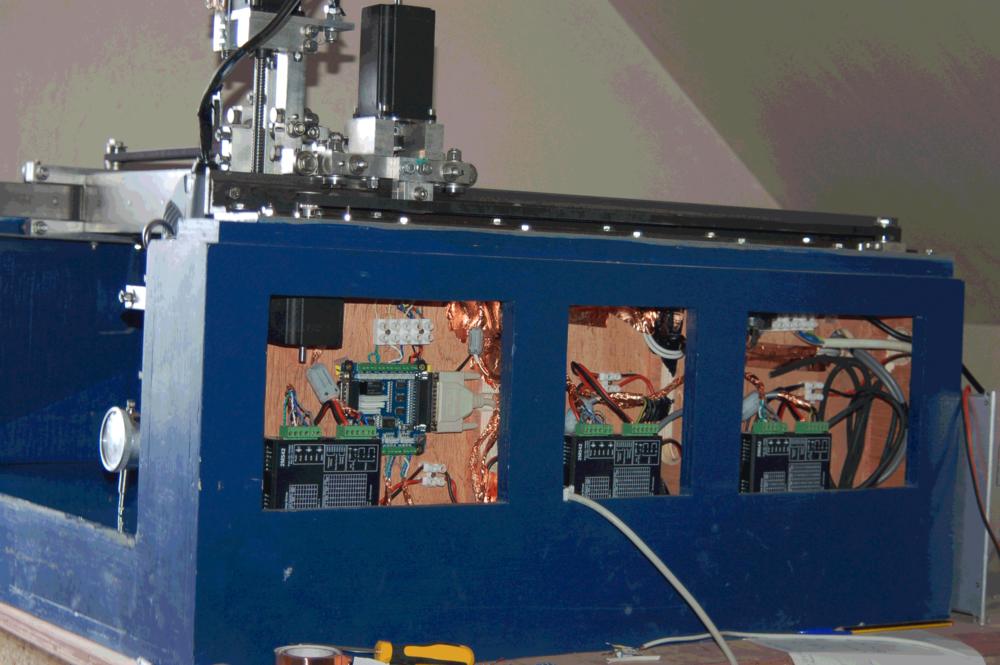

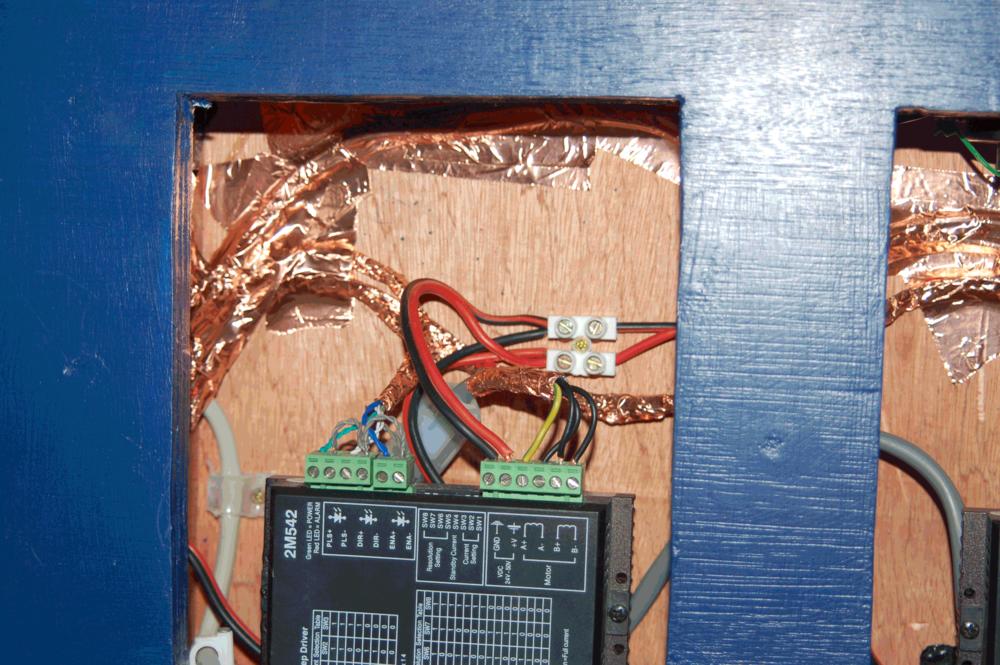

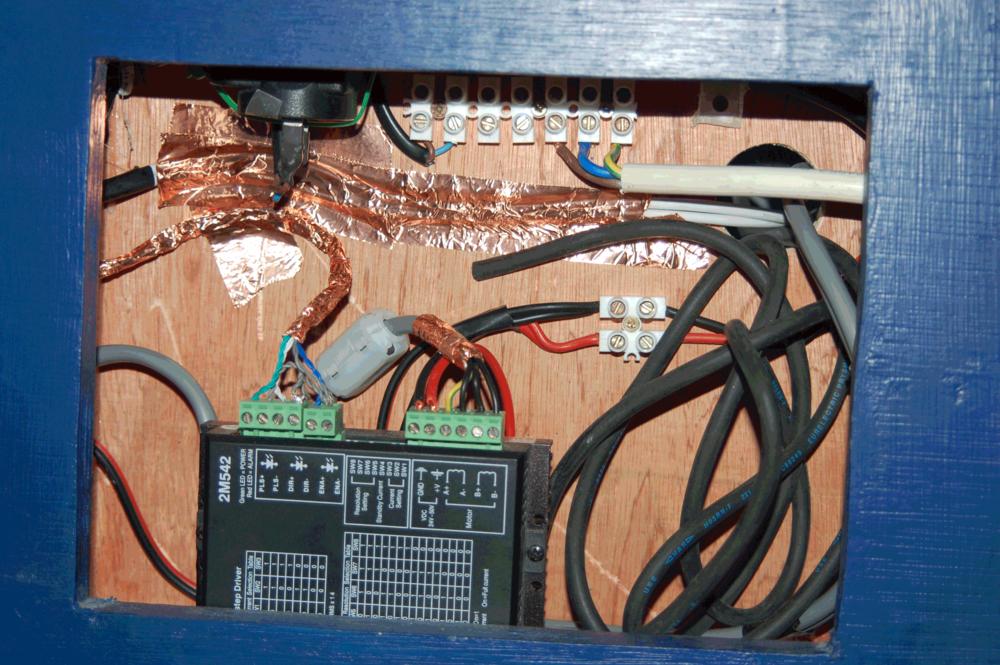

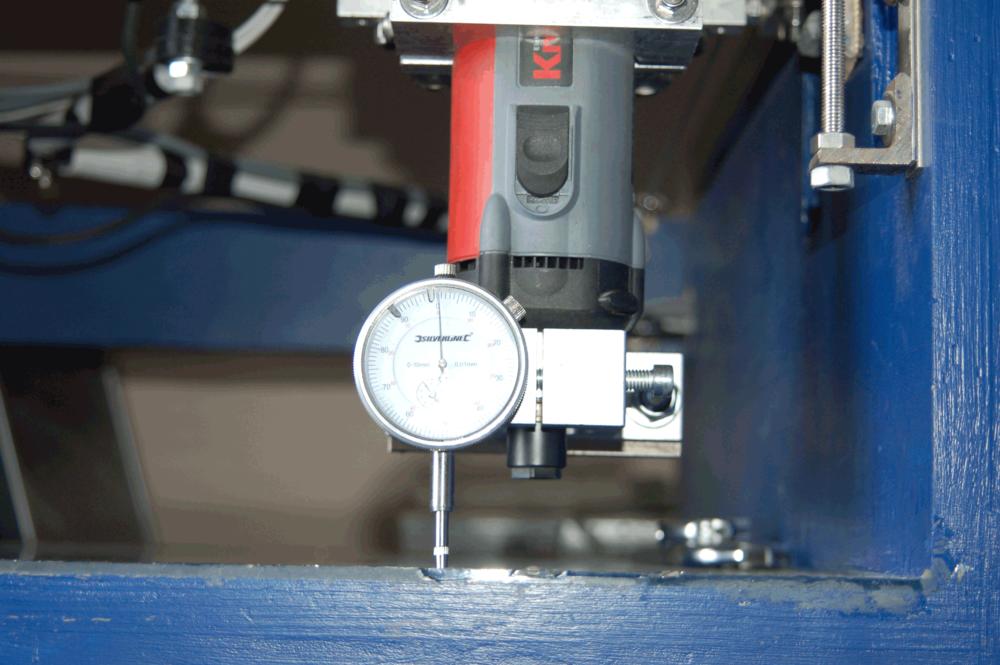

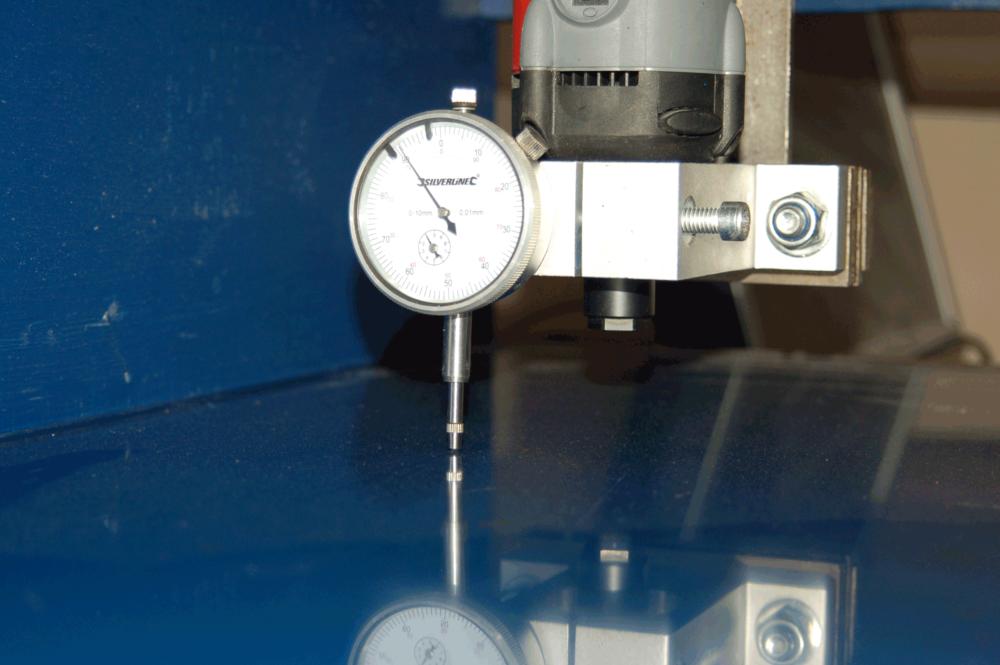

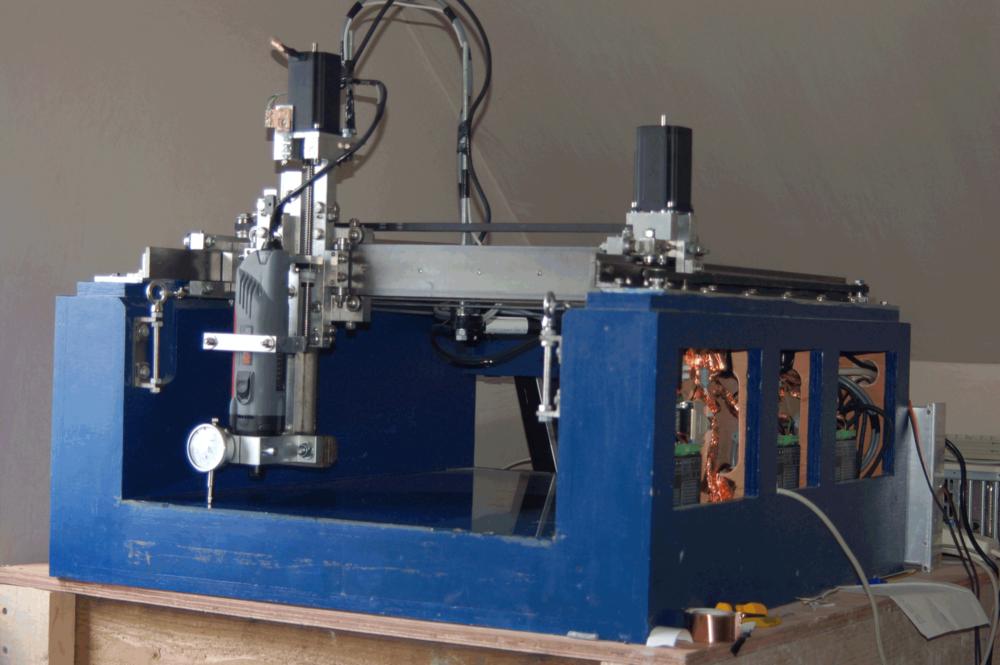

During the period 2012 to 2014 I constructed myself a high performance CNC to allow me to machine digital designs and realise my ideas more efficiently. This machine is capable of cutting materials such as wood and plastic along with non ferrous metals such as Aluminium, Copper and Brass to tolerances approaching 0.02mm. The ability to realise digital design in a physical form in such a short time period is such a fascinating and liberating process. This machine is essentially a computer controlled cutting machine: we design a part in a Computer Aided Design package (such as Google Sketchup), convert the resulting 3D model into machine code (GCode) using a secondary piece of software known as a CAM package. For a review of the subject areas surrounding the usage of CNC in small scale manufacturing, refer to the excellent resource here.

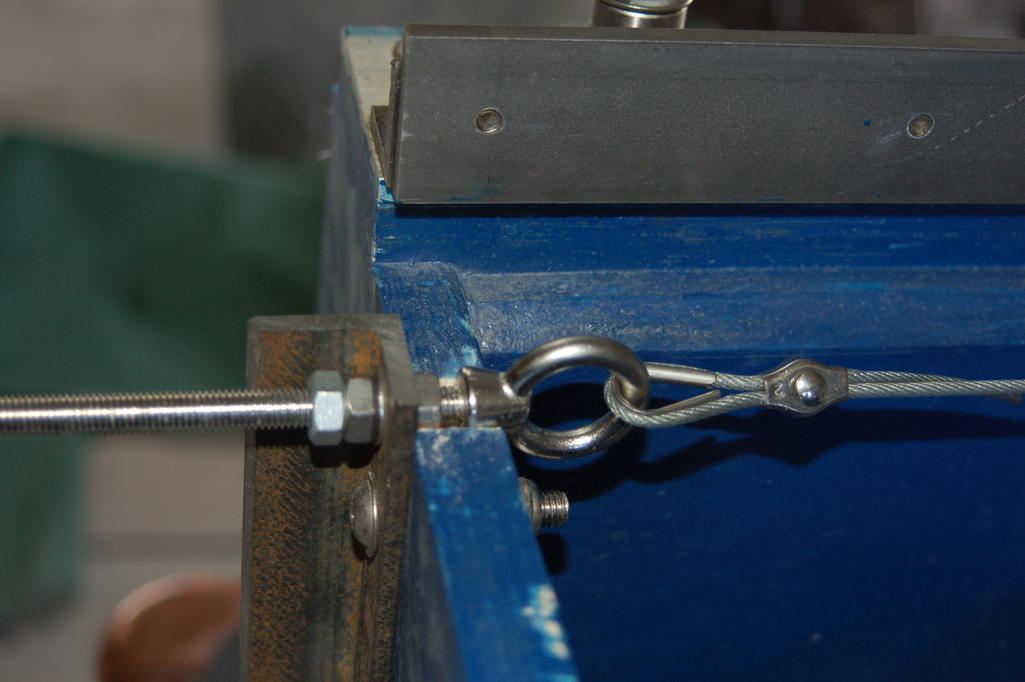

If someone had of informed me of just how difficult and lengthy this process would be I probably would never have approached it. I got there eventually and I am incredibly proud of being able to construct a device of such capabilities using little more than a hacksaw and a drill press (plus some blood sweat and tears).

The build, along with the trials and tribulations associated with it, are documented on a CNC forum called CNCZone. Rather than detail it extensively here please see the build thread for more information.

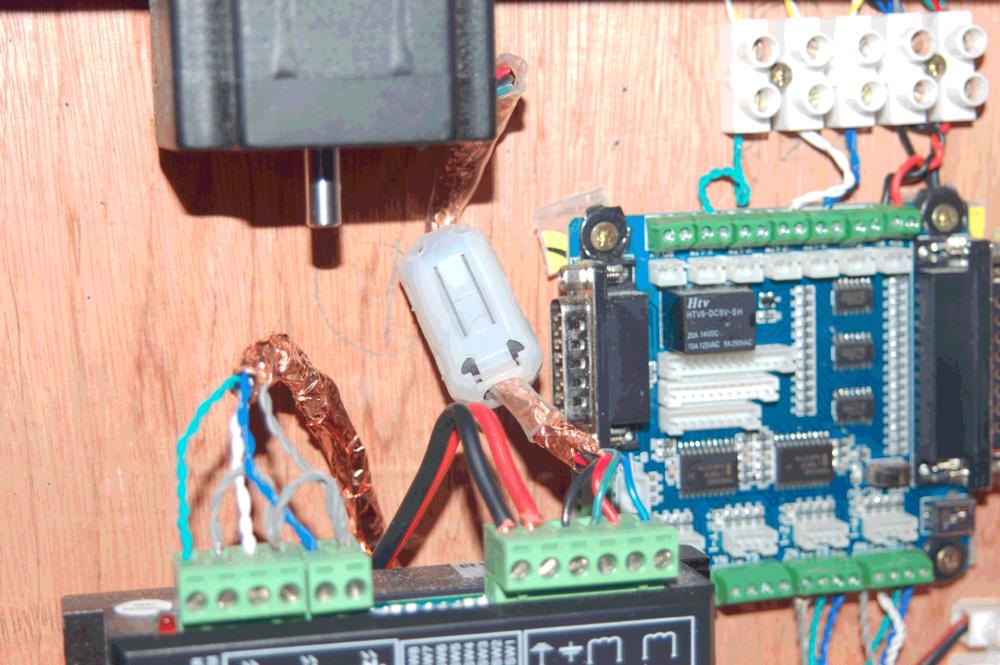

In addition to the CNC build, I also had to build a dedicated computer to drive it. Thanks to the help of the incredibly intelligent folks over at LinuxCNC. Specification details can be found in the forum post here.